Roger Walton Modelling Capability Lead

In a world of ever-increasing geopolitical threats, asset availability is crucial for the effectiveness of the UK’s defence capabilities.

Whether it’s aircraft, naval vessels, or ground vehicles, the ability to deploy assets swiftly and reliably can make all the difference in achieving and maintaining the warfighting edge.

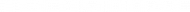

Maintaining high availability of complex, multi-role assets is a significant, multi-faceted challenge, influenced by numerous factors:

- Aging Equipment: Aging assets may be more prone to faults and will require extensive overhauls and spare part replacements, including components at risk of obsolescence.

- Maintenance and Repair: Limited resources, including skilled personnel and spare parts, can lead to delays in maintenance schedules.

- Budget Constraints: Budget constraints can lead to deferred maintenance, reduced spare parts inventories, and limitations on training for maintenance personnel.

- Supply Chain Vulnerabilities: Dependency on a complex and globalised supply chain can expose the UK’s defence sector to vulnerabilities such as disruptions in the supply of critical components or geopolitical tensions affecting the sourcing of materials.

- Technology Complexity: Modern defence systems are increasingly complex, incorporating advanced technologies and sophisticated components. Maintaining these systems requires specialised knowledge and resources, and risks issues with technology integration or obsolescence.

- Operational Demands: High operational tempo, frequent deployments, and mission demands can strain equipment and personnel, leading to increased wear and tear, fatigue, and reduced availability due to maintenance requirements or operational downtime.

- Human Factors: Human error, inadequate training, and workforce shortages can affect asset availability. A well-trained and motivated workforce is essential for maintaining and operating defence assets effectively.

- Lifecycle Management: Effective asset availability requires comprehensive lifecycle management practices, including acquisition, sustainment, and disposal phases. Inadequate planning or execution in any of these phases can lead to reduced availability during the operational lifespan of assets.

These challenges can vary across domains within defence, due to the differences in the equipment used and operational requirements:

- Maritime – larger naval vessels require extensive maintenance due to their complex systems and harsh marine environment. Often operating in remote locations for extended periods makes it challenging to accurately forecast and maintain a steady supply of spare parts and equipment.

- Air – modern aircraft require regular and often complex maintenance to ensure operational readiness. Flight schedules and maintenance can be affected by adverse weather conditions and emergent operational demands.

- Land – ground-based equipment requires regular maintenance to remain operational. The sheer size of the Land fleets along with rugged terrain, extreme climates, and hostile environments can impact challenges in maintaining equipment availability.

- Cyber and Information – defence forces rely on the availability and reliability of information systems, networks, and communication infrastructure. These systems are at risk of cyberattacks and disruption through enemy action, meaning this domain is both a priority and a challenge when it comes to maintaining specialist equipment availability and the flow of information across secure networks.

Figure 1: Asset availability challenges in Defence

Modelling is a technique that involves creating a simplified representation of a complex system or phenomenon to better understand, analyse, and make predictions about it. Check out our previous blog to learn more: Reduce Risk and Financial Uncertainty with Simulation Modelling.

It can play a significant role in improving asset availability by making the right information available, reducing manual analysis and providing insights to decision-makers quickly, to make better decisions.

- Predictive Modelling: By using data-driven models and algorithms, predictive modelling techniques can forecast equipment failures before they occur, enabling preventative maintenance tasks, or providing a clearer view of risk.

- Reliability Analysis: Reliability Modelling techniques help identify potential failure modes, assess their impact on asset availability, and prioritise maintenance activities to mitigate risks effectively.

- Simulation: Simulation models replicate real-world scenarios to evaluate the performance of maintenance strategies, resource allocation, and operational procedures. By simulating different scenarios, decision-makers can identify optimal approaches to maximise asset availability while minimising costs and risks.

- Supply Chain Optimisation: Modelling can optimise supply chain operations to ensure timely availability of spare parts and resources needed for maintenance activities. Supply chain models can analyse inventory levels, lead times, and demand variability to improve asset availability by reducing downtime due to spare parts shortages.

- Whole Lifecycle Cost Analysis: Whole lifecycle cost models assess the total cost of asset ownership over its entire lifespan, including acquisition, maintenance, and disposal costs. By considering various cost factors and trade-offs, decision-makers can make informed decisions to optimise asset availability while managing costs effectively.

- Resource Allocation: Modelling techniques such as optimisation algorithms can help optimise resource allocation for maintenance activities, such as labour, tools, and equipment. These models consider factors such as workforce availability, skill levels, and task priorities to maximise asset availability within resource constraints.

- Performance Monitoring: Models can continuously monitor asset performance metrics, such as reliability, availability, and maintainability to find trends, anomalies, and potential issues proactively. Real-time monitoring allows for prompt interventions to prevent downtime and optimise asset availability.

- Scenario Analysis: Modelling allows for the evaluation of different scenarios and strategies under various conditions, such as changes in operational requirements, maintenance schedules, or resource constraints. By conducting scenario analysis, decision-makers can assess the potential impact of different decisions on asset availability and make informed choices.

Techmodal has used various techniques to allow our clients to make better decisions about how they can operate their equipment and increase availability.

- Asset failure prediction: We have used Machine Learning models to accurately predict asset failure events by identifying patterns and learning from historical precedents. This has been embedded into our toolsets to help operational planners, logisticians and engineers reduce failure rates and ensure high platform availability.

- Fleet Management Modelling: We have applied simulation techniques across Land, Maritime and Air fleets. Our approach modelled a platform’s in-service lifetime allowing for different approaches to fleet management to be compared empirically. Using cost modelling data, a cost/benefit analysis of scenarios enabled a clear understanding and balance of the cost of unavailability versus the cost of policy implementation.

- We have constructed numerous Whole Life Cost Models (WLCMs) for various platforms across UK Defence allowing for the lifecycle of costs to be understood and scenarios to be compared.

- Techmodal’s flagship tool VERITAS, a bespoke data-driven application suite for the British Army, offers enterprise modelling capability on complex Defence data sets, including:

- Supporting the Army in generating a forecast of planned training and operation activity which includes various forms of inventory, across vehicle equipment and parts, commodities such as rations and fuel, and the global ammunition stockpile.

- Converting forecasted activity into a fully costed equipment supply and repair plan, underpinned by granular financial analysis and forecasting.

- Allowing the Army to monitor the quantity and cost of consumption at Front Line units to understand forecast accuracy and trends of reliability. This feeds into Army fleet management and decision support for improving the reliability and availability of equipment.